Fuel injection laboratory

Fuel injection is one of the dominant processes in diesel engine combustion and determines emissions. In view of increasingly stringent emission limits, continuous research and development of injection technology and an improved understanding of the decisive processes and interrelationships are essential prerequisites for future engines.

The department of Piston Machines and Combustion Engines at the University of Rostock has for many years been conducting a wide range of experimental and theoretical analyses to characterise and improve the mixture formation processes. Due to the LKV's proximity to marine diesel engines, it has particular experience with marine fuels and injection systems. Accordingly, the LKV has all the facilities required for analysing and handling heavy oils. It also has extensive experience with alternative fuels and injection systems for passenger car and commercial vehicle engines.

The continuous work on publicly funded research projects and the consistent integration of student research projects, as well as the presentation of current research results in lectures, make a significant contribution to the training of highly qualified graduates in the Department of Mechanical Engineering and Marine Technology with extensive specialist knowledge in the field of injection and mixture formation.

Focus

- Analysis of sprays and injection processes from passenger car injectors to injectors for medium-speed large diesel engines

- Support for all engine projects through expertise and component analyses

- Development of measurement methods and evaluation tools

- Heavy fuel oil and other special fuels

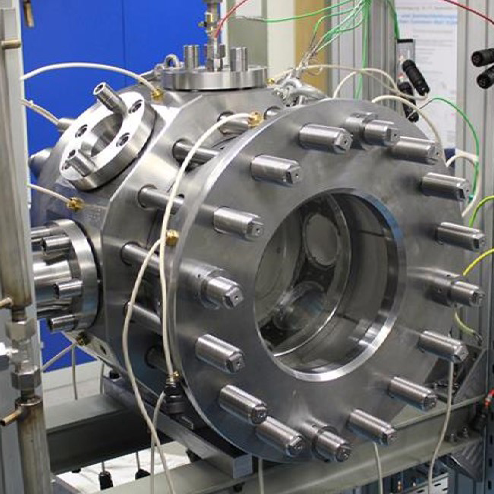

High-pressure, high-temperature spray chamber (Ø 300 mm)

Technical data of the test bench:

- Optical access Ø 300 mm

- Maximum chamber temperatures up to 900 K

- Pressure resistance tested up to 250 bar

- Common rail system with pressures up to 2200 bar

- Compatible with injectors from heavy-duty to medium-speed diesel engines

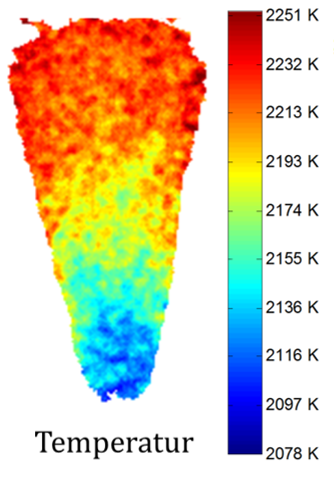

Measurement techniques used:

- Schlieren scattered light for visualisation of the liquid and vapour phases of an evaporating fuel spray

- Soot lights for analysis of combustion with regard to flame lift-off, ignition locations, flame temperature

We offer contract measurements with a focus on:

- Visualisation of innovative combustion concepts

- Comparison of different nozzle geometries and injector systems

- Support for single-cylinder engine tests

- Effect of nozzle wear and ageing

- Alternative and unconventional fuels

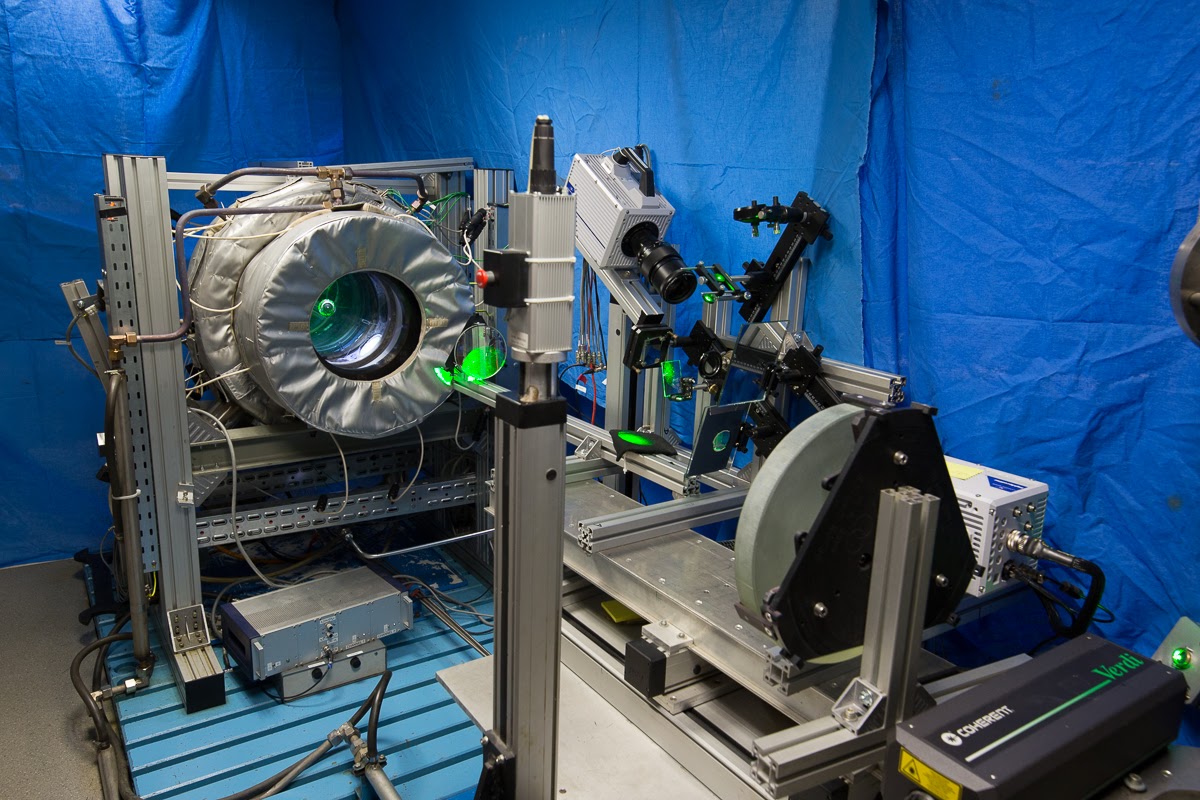

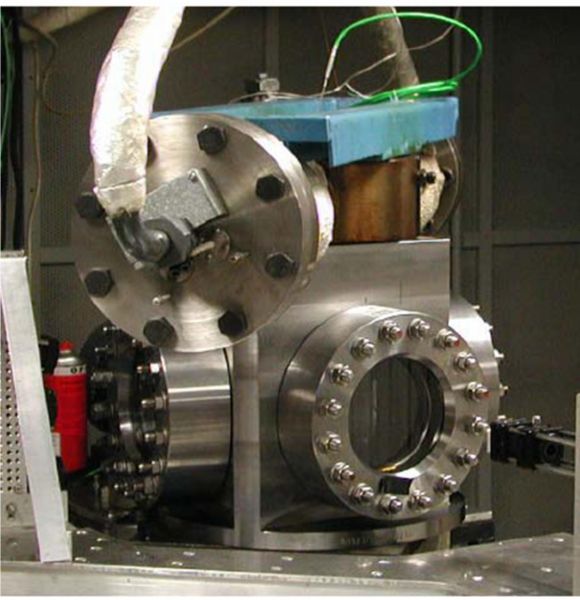

High-pressure, high-temperature spray chamber (Ø 130 mm)

- Observed jet lengths up to 130 mm

- Chamber pressures up to 60 bar

- Temperatures up to 850 K

- Optical access from 3 sides

- Common injection systems can be used

- Suitable for heavy fuel oil

- Fuel can be conditioned

Injection Rate Analyser

Focus of investigation:

- Measurement of injectors up to a cylinder power of 500 kW

- Injection sequence durations up to 24 ms

- Static back pressure up to 150 bar, dynamic up to 300 bar

- Specially developed correction and evaluation routines

- Influence of alternative and unconventional fuels on small quantity capability

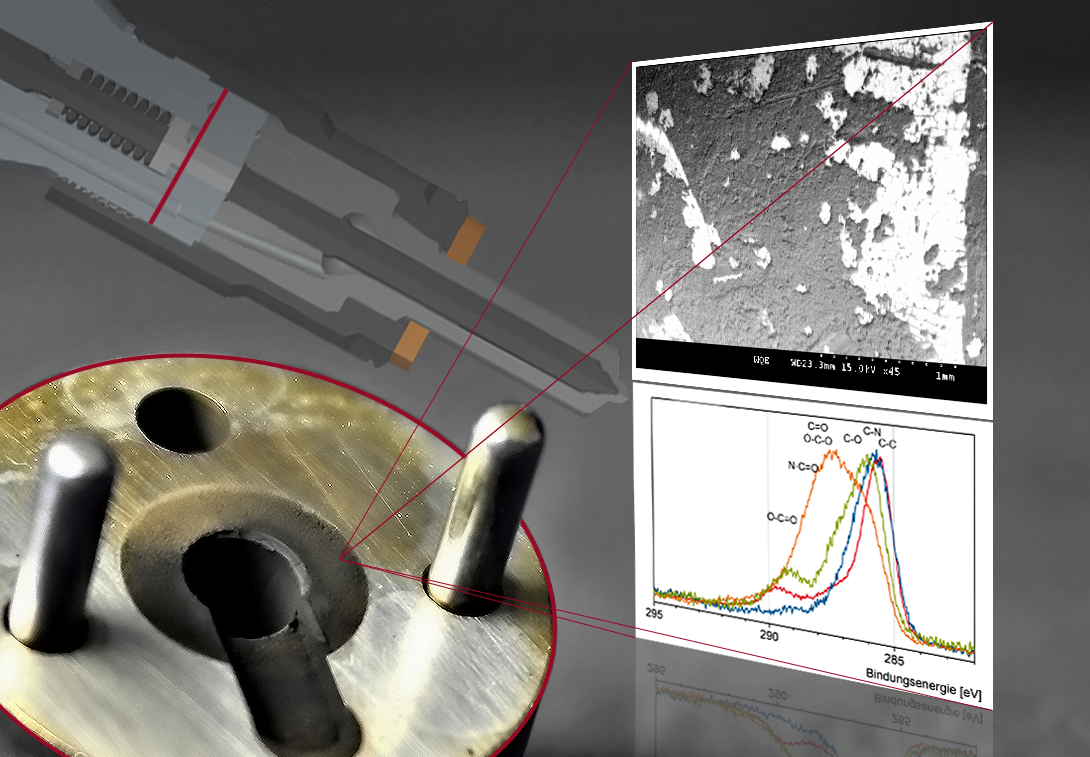

Injection System Test Bed

Main areas of investigation:

- Analysis of the potential of diesel and special fuels for deposit formation in diesel injectors

- Analysis of the sensitivity of the tendency to form deposits with regard to

- Operating life

- Operating temperature

- Fuel additives

- Oxygen content in the fuel

- Individual temperature control of components

- Tests in open loop (transferable to engine tests) and closed loop (return of the injection quantity to the tank)

- High transferability of the results to other standard engine tests

- Significantly lower test costs and higher reproducibility of the results compared to engine tests

Test bench boundary conditions:

- System pressures up to 2500 bar

- Fuels – non-compliant diesel, HVO, rapeseed oil Extension for heavy oil use available

- Injectors from 5 – 200 mm³/stroke

- System temperatures ≤ 160°C

- Stationary/transient operating mode

- Start/stop operation

- Open loop – real fuel flow

- Close loop – return of all fuel to the day tank

- Rail pressure control – FI²RE

- Data acquisition/monitoring/control/regulation – LabView

- Control of solenoid valve and piezo injectors – FI²RE

- Fully automated endurance runs > 300 hours