DGMK 859 No-Harm Test fo Additives

Development of a No-Harm Application Test for Additives - Investigations with the Diesel Deposit Formation Test as well as the ENIAK test bench test

Duration: 1.10.2022-31.03.2025

Funded by: BMWK/ AiF IGF /DGMK

Cause and aim

For the testing of additives and the avoidance of undesirable side effects in diesel fuels, there is a catalogue of criteria agreed upon by the mineral oil and additive industries. Among other things, this catalogue contains an engine application test for injector coking (XUD-9 CECF-23-01). This CEC-certified XUD9 test is based on outdated technology and in particular the increasingly difficult spare parts situation requires a suitable alternative in a timely manner. The CEC replacement test (DW10b) intended for this purpose is generally considered by the industry to be too expensive and often unsatisfactory in terms of technical/scientific significance.

The aim of the joint project is therefore to develop a suitable and cost-efficient no-harm application test for additives to replace the obsolete XUD-9 engine test (CECF-23-01).

The new test method should cover both current and future fuel and additive technologies as well as injection concepts. Furthermore, it is intended to be meaningful not only for external (EDID) but also for internal injector deposits (IDID), which are becoming increasingly relevant.

Brief description

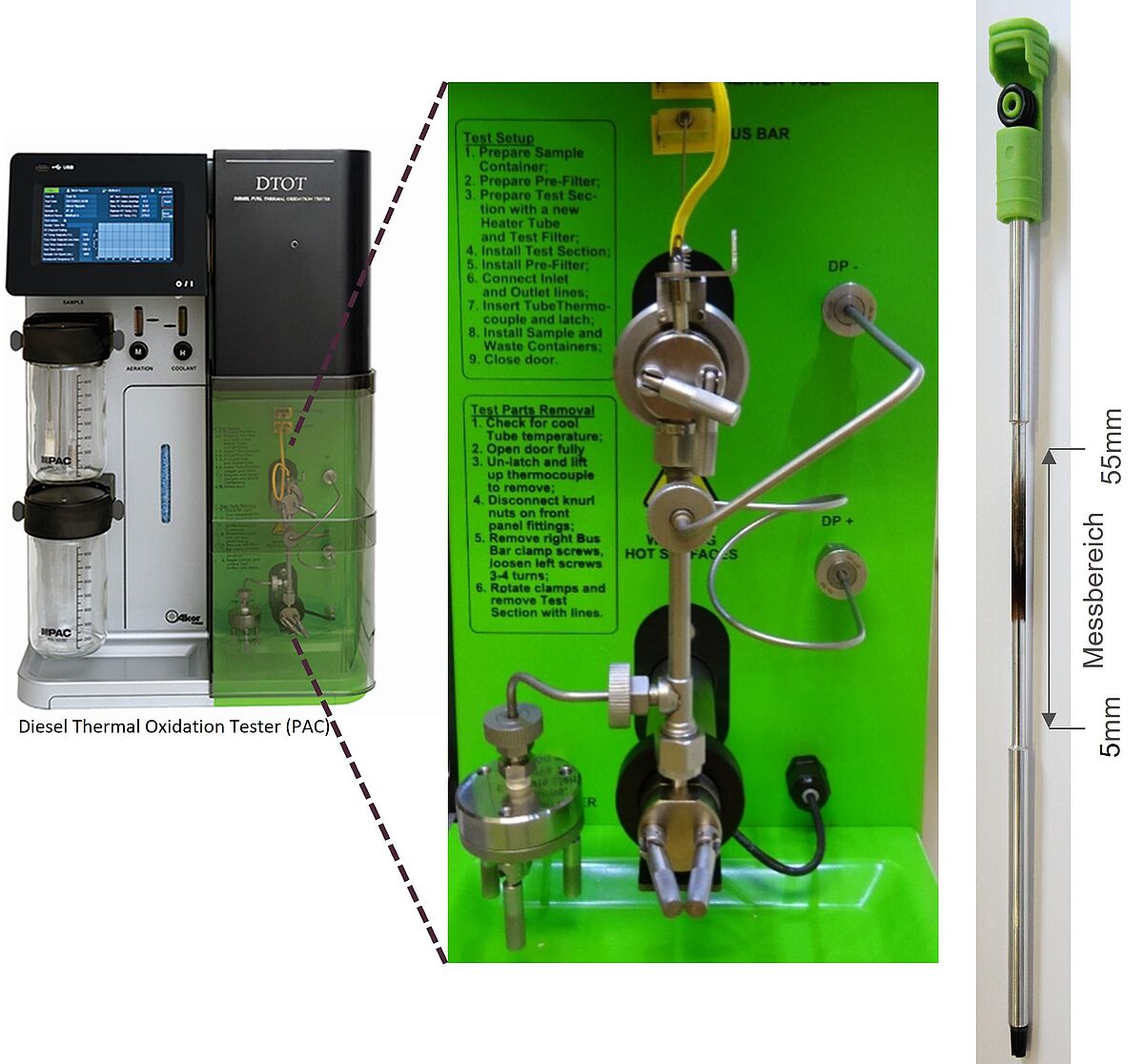

The subject of the method development is a combination of two complementary concepts, the "Diesel Deposit Formation Test" (DDFT, LKV) as a laboratory test and an application-oriented injector coking test ("ENIAK", OWI). Within the scope of the project, suitable boundary conditions, fuel references and evaluation criteria for the additive tests are to be developed first (setting a basic performance). Subsequently, numerous fuel-additive combinations of antioxidants, cold flow improvers and lubricity improvers will be comparatively investigated and evaluated. The results of the method development are documented in detail and made available to interested companies in a timely manner.

Currently, no-harm testing of additives is very time-consuming and expensive. Therefore, there is innovation potential here for small and medium-sized enterprises, e.g. additive formulators, analysis service providers, equipment manufacturers, to bring new products to the market faster and more cost-effectively or to open up new business areas. Cost-effective screening by means of laboratory tests will make it possible to avoid expensive test bench tests in the future. At the same time, self-directed tests will be possible. IDIDs that occur can be detected sooner thanks to modern analysis technology and thus warranty cases in the field and recourse claims by customers can be reduced or avoided.

Link:

Development of a No-Harm Application Test for Additives -

Investigations with the Diesel Deposit Formation Test as well as the ENIAK test bench test

Research Partners:

- University of Rostock, Department of Piston Machines and Internal Combustion Engines

Prof. Dr.-Ing. Bert Buchholz, Dr. Ulrike Schümann, Dr. Katharina Wulf

- OWI Science for Fuels gGmbH

An-Institute of the University RWTH Aachen - FS-Leitung: Dr. Wilfried Plum,

Sebastian Feldhoff