Focus of our Research

The LKV's machine laboratory focuses on the following areas:

- Alternative fuels for cars and lorries

- Gas operation of engines

- Heavy fuel oil operation of engines for maritime shipping

- Thermal component stress

- Emissions from combustion engines

- Analyses and tests of engine lubricating oils

The engine laboratory also has cutting-edge modular combustion chamber endoscopy technology from AVL.

This measurement technology enables optical analyses in the combustion chambers of combustion engines under real engine operating conditions.

The following effects can be analysed, among others:

- Analysing ignition locations, flame fronts and reaction zones based on the flame's luminescence

- Analysing fuel injection, the distribution of the liquid fuel phase before the start of combustion and fuel-wall interactions by means of scattered light measurements using additional endoscopic light sources

- The investigation of soot formation and burn-off due to soot luminescence, as well as

- The determination of flame temperatures using the flame-colour method

for a wide variety of fuels, especially renewable fuels.

Funded by the German Research Foundation (DFG) - project number 649600

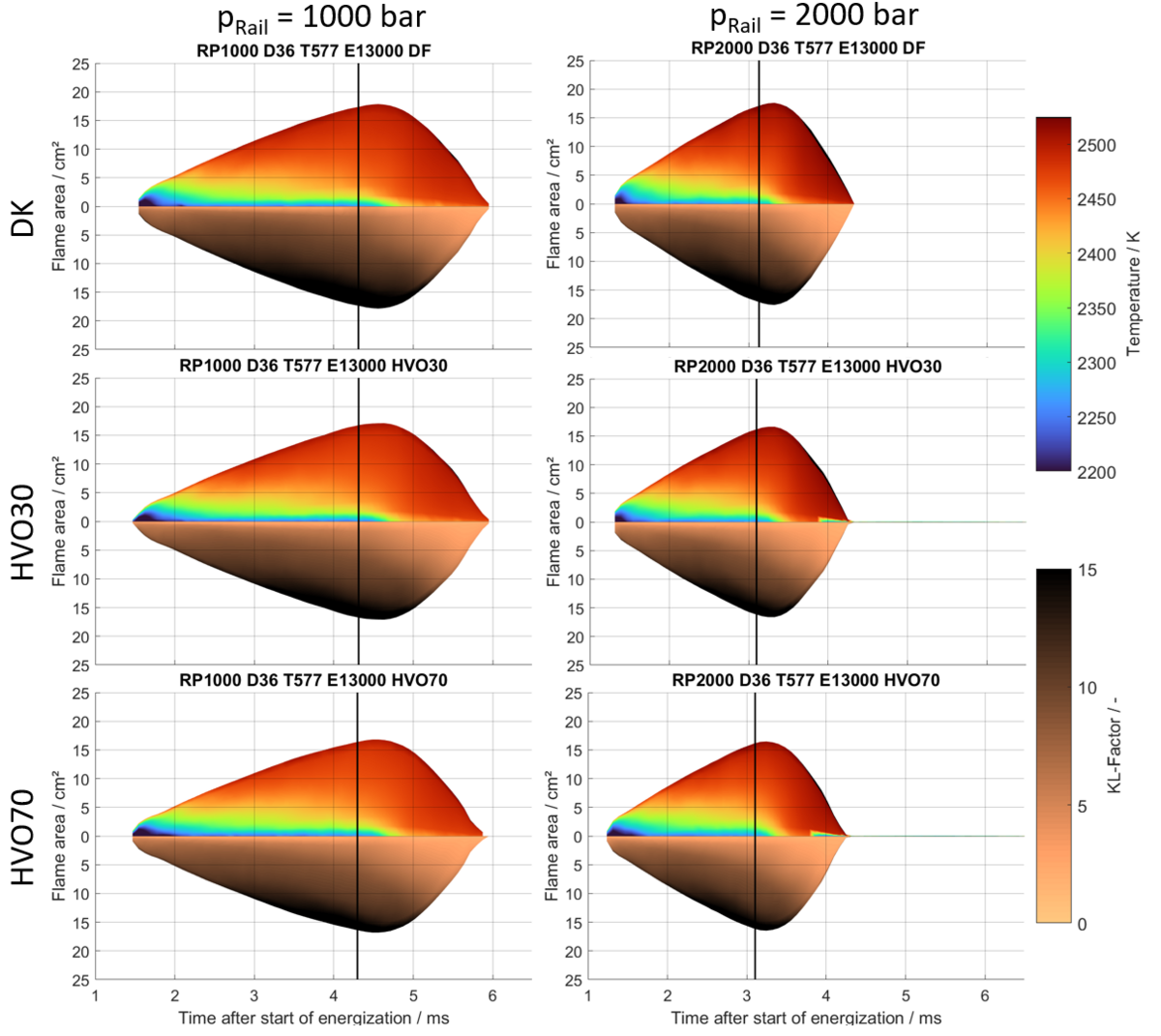

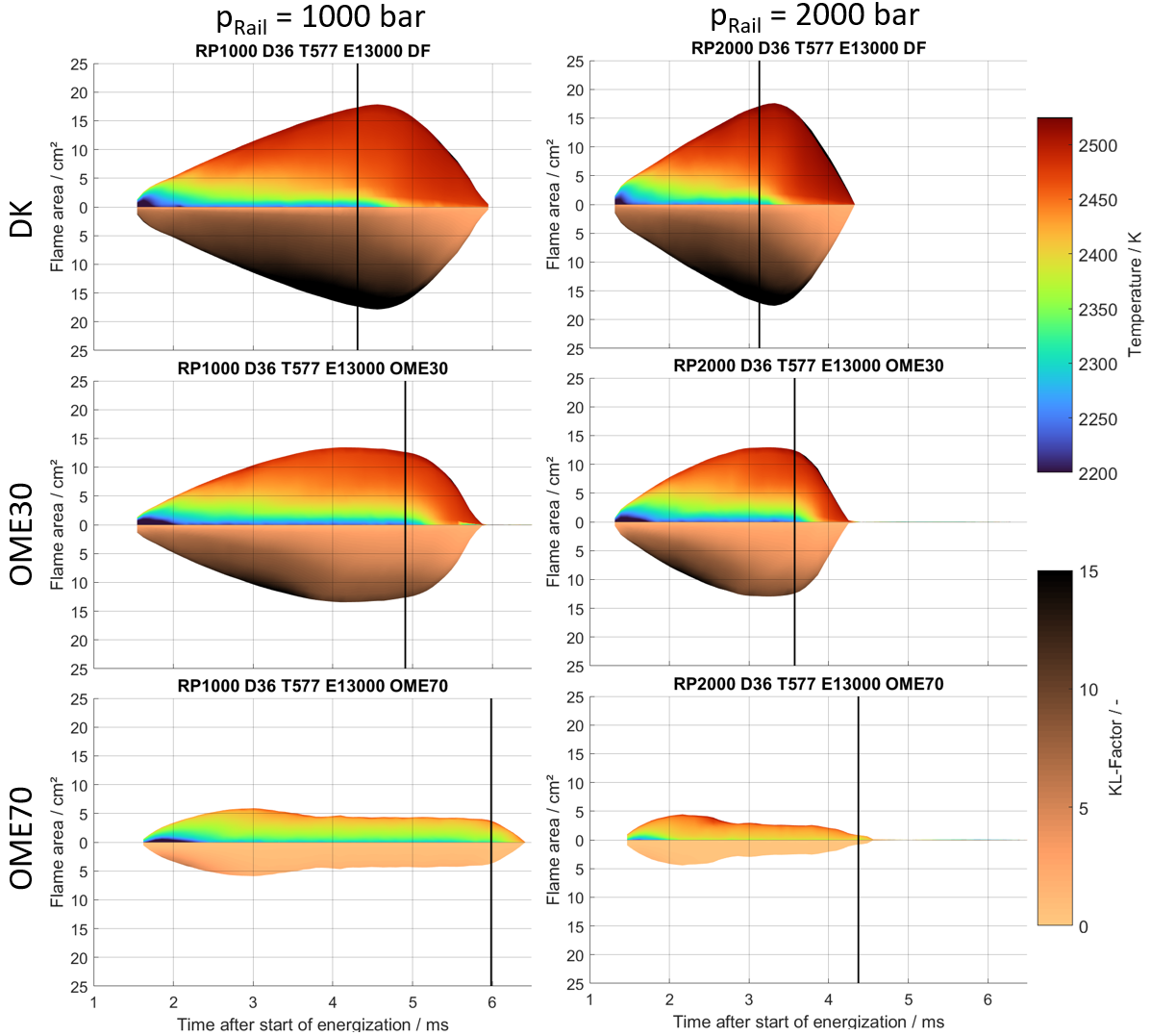

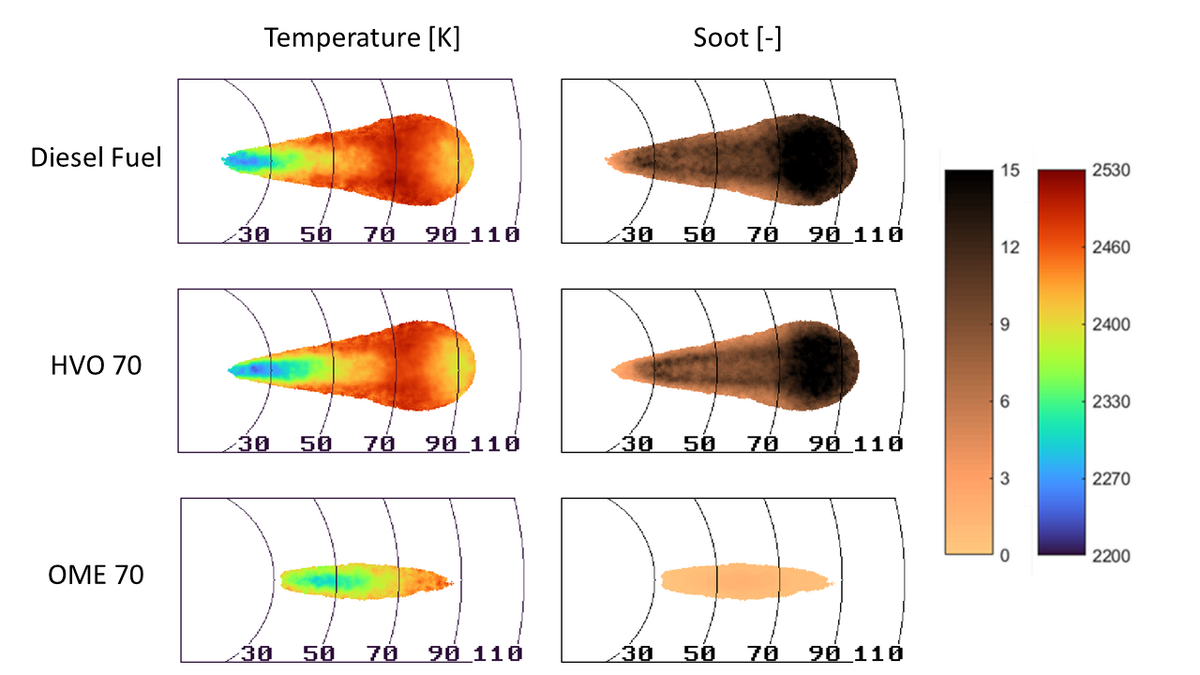

High-speed images of the burning spray are evaluated using a 2-colour pyrometry method to produce plots of flame temperatures and soot concentrations. The results are used to compare alternative fuels in different blending ratios with diesel fuel.

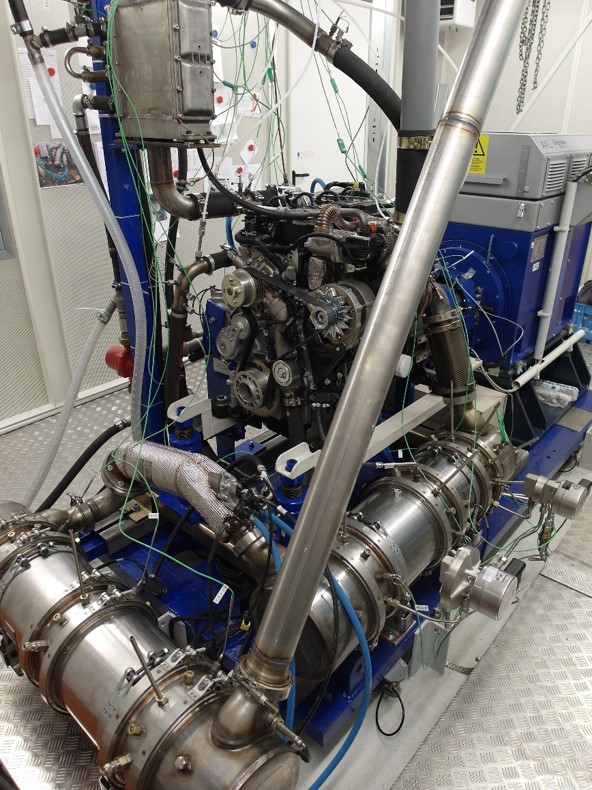

Test bed 16: Medium-Duty Single Cylinder 1TCD5.2

Test bed 16 is structured as follows:

Test Bed:

- 4-quadrant dynamometer

- Stationary and transient engine operation

- For medium-duty engines up to 220 kW

- Fuel supply: diesel, gasoline, CNG (40 bar), hydrogen (50 bar), ammonia (liquid/gaseous)

- Coolant and lubricant conditioning

- Diesel injection: common rail up to 1600 bar

- PFI injection: ammonia (up to 10 bar), hydrogen (up to 15 bar)

- Boosting via external charge air supply (up to 4 bar, 10–100 °C)

- Freely programmable engine control unit for development purposes

- Extensive externally heated exhaust system for investigation of different catalyst technologies (up to 4 substrates, each 150 × 150 × 300 mm), including two NH₃ dosing positions

Currently Installed Engine / Power Unit:

- Single-cylinder research engine based on DEUTZ TCD 5.2 / TCG 7.8 H₂

- Engine type: 4-stroke, 1 cylinder, 4 valves

- Stroke: 136 mm

- Bore: 110 mm

- Displacement: 1.29 L

- Rated power: 45 kW at 2,300 rpm

- Compression ratio: 10 to 17.5 (various piston variants available)

Test Bench Monitoring:

- Engine operation monitoring via LabVIEW-based test bench supervision software

- Safety system for gas engine operation

Indication System:

- Kistler KiBox2 (cylinder pressure, intake and exhaust pressure, NH₃ and H₂ injection pressure, diesel injection pressure)

- In-house pressure trace analysis tool

Exhaust Gas Measurement Equipment:

- MKS MultiGas 2030G FTIR (in IAG Versa06)

- ABB Fidas24 FID – HC measurement

- ABB Magnos28 – O₂ measurement

- MS4 Hsense – H₂ measurement

- AVL Smoke Meter

Ongoing Projects:

Test Bench Engineer:

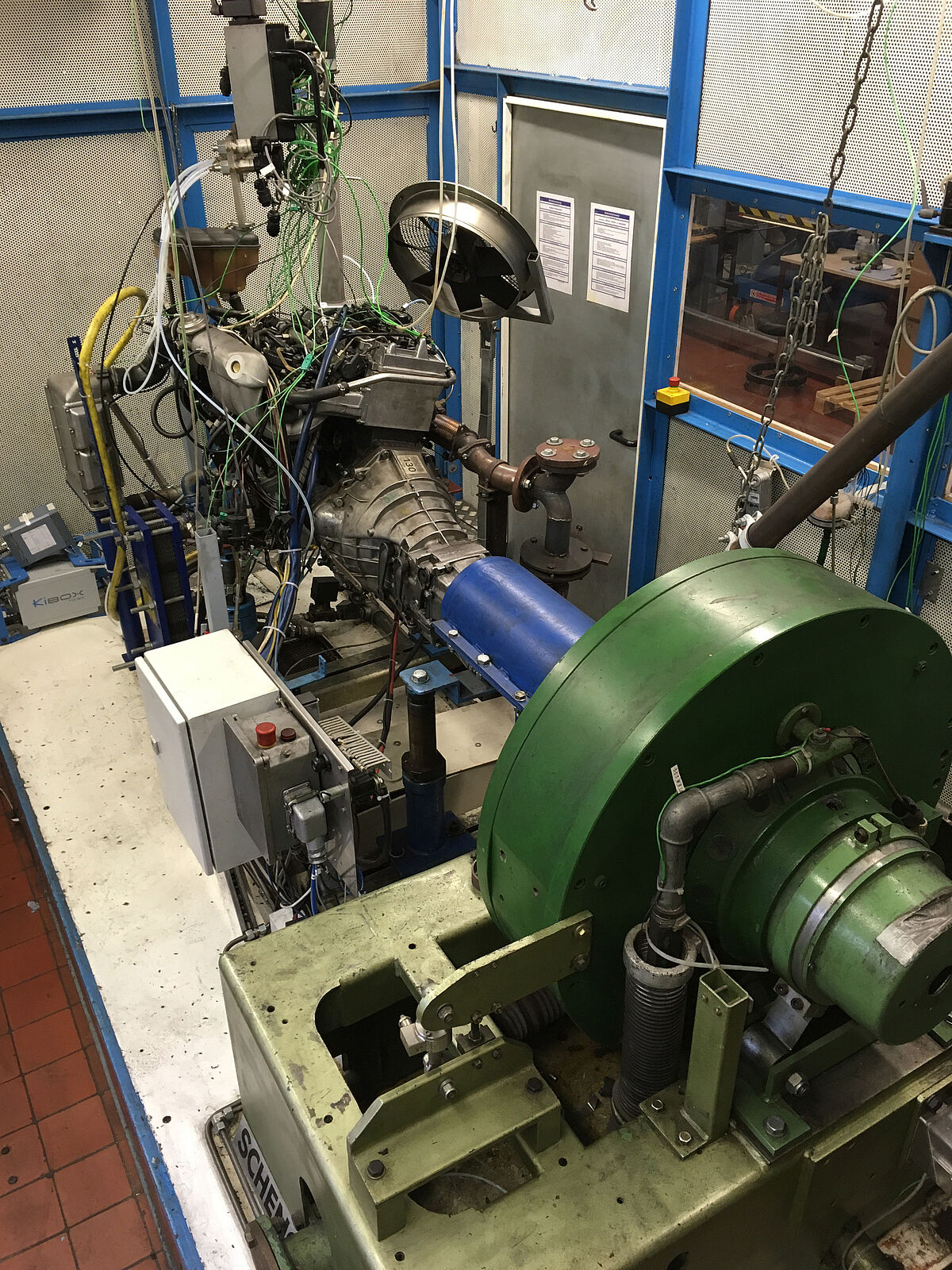

Test bed 0: AUDI 2.0l TFSI

Fully automatic car engine test bench consisting of:

- 4-quadrant dynamometer

- AVL PUMA test bench control

- Stationary and dynamic operation possible

- For car engines up to 220 kW/ 8,000 min-1

- Fuel and air flow measuring devices

- Pressure and temperature monitoring

- FTIR exhaust gas measuring system

- Oximat

Technical data:

- AUDI 2.0l TFSI petrol engine

- Engine design: 4-cylinder, 16 valves

- Displacement: 1,984 cm³

- Bore: 82.5 mm

- Rated power: 140 kW at 4,180 min-1

- Max. Torque: 320 Nm at 1,500 min-1

- Exhaust gas aftertreatment: Three-way catalytic converter

- Fuel injection: DI injection system

- Exhaust gas turbocharger

Measurement of:

- Air and fuel mass flow rates

- Blow-by volume flow

- Pressures and temperatures within the engine

- Data from the engine control unit

- Exhaust gas composition (FTIR+Oximat)

- Composition of blow-by gas and cylinder charge

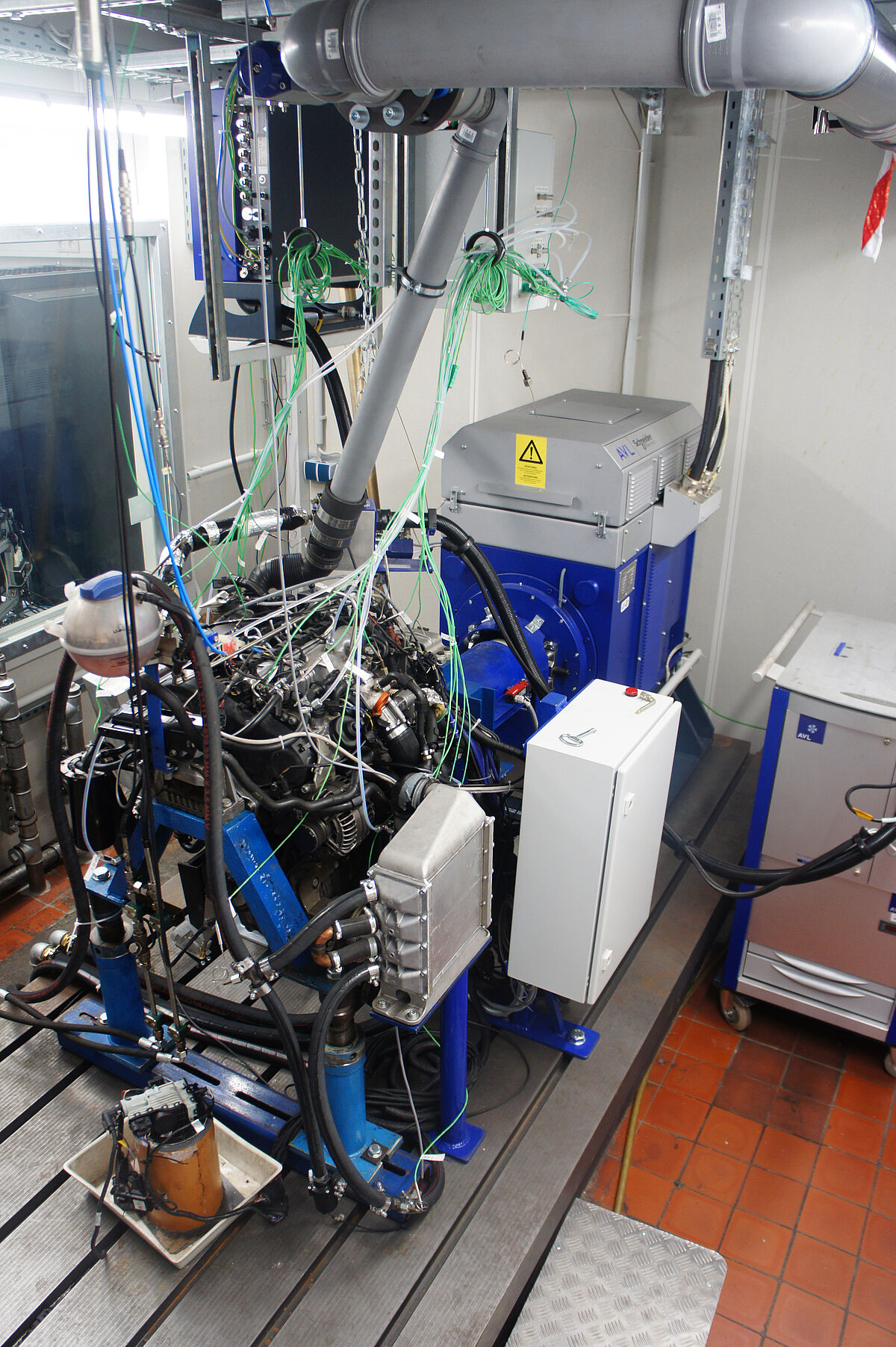

Test bed 1: Caterpillar MaK 6M20

A Caterpillar MaK 6M20 full engine serves as the basis for engine test bed 1.

Technical data and equipment:

- Type: medium-speed 4-stroke marine diesel engine

- Design: 6 cylinders

- Output: 190 kW/cyl. or 1,140 kW total

- Bore: 200 mm

- Stroke: 300 mm

- Nominal speed: 1,000 min-1

- Rail pressure >1,500 bar

- Freely programmable control unit

Analysis of:

- Fuel consumption and air mass flow rates

- Pressures and temperatures within the engine

- Combustion behaviour through pressure indexing

- Exhaust gas composition

Test Bed 2: 1 VDS 18/15

Technical data:

- 1-cylinder engine suitable for heavy fuel oil

- 4-stroke engine

- Stroke: 180 mm

- Bore: 150 mm

- Nominal speed: 1,500 min-1

- Rated power: 80 kW

- Common rail injection

- Separate fuel systems for distillate and heavy fuel oil

- Freely selectable charge and exhaust back pressures

- 4-quadrant brake

- Access for optical and laser-optical analyses

Ongoing projects:

Test bed 3: Deutz TCD 3.6 L04

Test bed 3 is set up as follows:

- Dynamometer: 4-quadrant

- Stationary and dynamic engine operation

- For lorry / truck engines up to 220 kW at 2,250 min-1

Engine characteristics:

- Engine design: 4-cylinder, 8 valves

- Stroke: 120 mm

- Bore: 98 mm

- Rated power: 100 kW at 2200 min-1

- Max. Torque: 500 Nm at 1600 min-1

- Exhaust gas aftertreatment: DOC, DPF, SCR, ASC

- Fuel injection: Common rail injection system

- Cooled external exhaust gas recirculation

- Exhaust gas turbocharger

Measurement of:

- Fuel consumption and air mass flow rates

- Pressures and temperatures within the engine

- Data from the engine control unit

- Exhaust gas composition

Analysis of:

- Engine behaviour in biodiesel operation

- The influence of biodiesel on the exhaust gas aftertreatment system (AGN)

- The long-term stability of the engine and the AGN system in biodiesel operation

Test bed 9: VW 2.0 L TDI CBAC

Fully automatic car engine test bench consisting of:

- 4-quadrant AVL dynamometer

- Stationary and transient engine operation

- AVL ISAC 400 vehicle/driver simulation

- AVL PUMA test bench control

- Freely configurable IAV FI2RE control unit

- Online indexing via AVL Indicom

- Fuel and air flow measuring devices

- Pressure and temperature monitoring

- Soot measurement via AVL Smokemeter

- Particle count and size determination via AVL APC and EEPS

Engine with the following characteristics:

- VW 2.0 l TDI CBAC (EURO 6)

- Engine type: 4 - cylinder, 16 valves

- Stroke: 95.5 mm

- Bore: 81 mm

- Rated power: 103 kW at 4,200 rpm

- Max. Torque: 320 Nm at 1,750 to 2,500 rpm

- Common rail injection with piezo injectors

- Turbocharging with VTG charger

- Cooled high-pressure EGR

- Exhaust gas aftertreatment: DOC - DPF - SCR

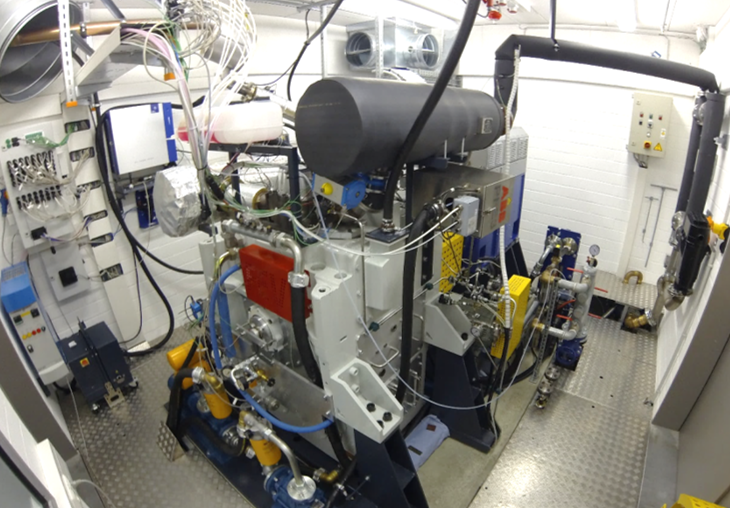

Test Bed 15: Caterpillar 1M34DF

Test bed 15 is set up as follows:

- Dynamometer: 4-quadrant

- Stationary and dynamic engine operation

- For medium-speed engines up to 850 kW at 1000 min-1

Engine with the following characteristics:

- Engine design: 1 cylinder, 4 valves

- Stroke: 460 mm

- Bore: 340 mm

- Rated power: >500 kW

- Nominal speed: 750 min-1

Special features of the test bench:

- Powerunits up to 350 mm bore and 500 mm stroke can be installed

- External supercharging up to 8 bar overpressure

- Charge air preheating

- Natural gas infrastructure up to 20 bar /100/ 500 bar for SOGAV PFI and direct gas injection

- Open ECU based on NI components

- Charge air humidification

- Addition of Propane and CO2 to simulate worldwide LNG qualities

Measurement of:

- Fuel consumption and air mass flows

- Exhaust gas composition (FTIR)

- High and low pressure indexing

- Fuel gas quality using a natural gas chromatograph

Analysis of:

- the engine behaviour in dual-fuel operation

- the influence of different fuel gas qualities on operating behaviour

- the influence of different ignition concepts

Ongoing projects:

Test bed 17: Heavy Duty Single Cylinder Research Engine

Test bed 17 is set up as follows:

- Dynamometer: 4-quadrant dynamometer

- Stationary and dynamic motor operation

Engine characteristics:

- Engine type: 1 - cylinder

- Engine type: Diesel

- Displacement: 2.5 litres

- Bore: 140 mm

- Rated power: 125 kW

- Max. Engine speed: 2,300 min-1

- Max. Cylinder pressure: 250 bar

- Injection: Common rail system (up to 2,200 bar)

- Variable EGR system

- Supercharging: external, up to 5 bar

- Flexible use of different injectors possible

Indexing technology:

- AVL Indiset

- In-house pressure curve analysis tool

- Exhaust gas measurement technology:

- AVL i60 - FTIR

- AVL SmokeMeter

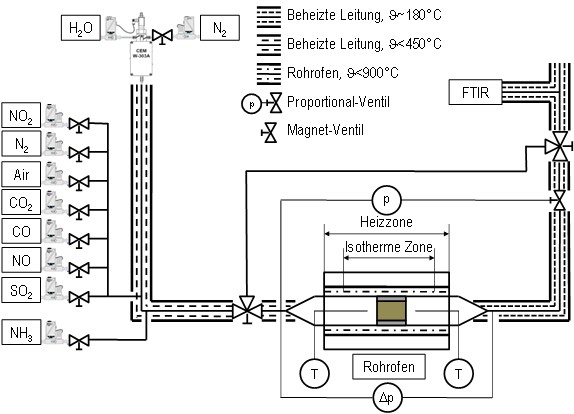

Synthetic Gas Test Bench

The synthetic gas test bench allows a free choice of parameters when creating a synthetic exhaust gas:

- Temperature

- pressure

- gas composition (N2, O2, CO2, H2O) and emissions (e.g. HC, CO, NOx, SOx)

- Analyses also possible outside the usual engine operating window without risk of engine damage.

- Automation for reproducible measurement of exhaust catalytic converters

- Benchmark/comparison of different manufacturers

- Effects of ageing mechanisms on catalytic converter performance

- High quality and reproducibility of measurements minimise measurement errors

- Separation of reactions and reaction paths possible

- Many reactions take place simultaneously in real exhaust gas

- Individual reactions can be analysed using specific exhaust gas composition and temperature ranges

- Determination of model parameters for individual reactions from measurement data possible.