AVL PUMA 2™ automation platform

With the support of the European Regional Development Fund (ERDF) as part of the 2021-2027 programme "Strengthening research and innovation capacities and the introduction of advanced technologies", an AVL PUMA 2™ automation platform for drive test benches was put into operation on 15th of September 2025

The AVL PUMA 2™ automation platform enables research operations on combustion engines and hybrid drives. The automation platform can be coupled with a virtual electric machine via software, which reduces the amount of real hardware required for hybrid operation. This was not possible with the existing test benches. The use of the virtual electric machine is particularly useful for large stationary motors, as more space-intensive and expensive electric motors do not have to be installed. This will enable the expansion of research into new, future drive strategies with gaseous and liquid alternative fuels for shipping and agriculture.

The following investigations are possible with the new automation platform on the engine test bench for off-road drives:

- Testing and development of hybrid drives for agricultural and construction machinery

- Emission testing of engines in ammonia operation with rapid load changes

Testing of gaseous e-fuels (DME and hydrogen) under reproducible conditions as comparative measurements to conventional fuels

Testing of e-fuels that can/should serve as a replacement for fossil diesel

- Investigations into the transient operating behaviour of volatile e-fuels and their blends (e.g. methanol, methanol blends); a key point here is starting at very low temperatures or very high temperatures, where fuel can evaporate/volatilise during downtime

- Automated endurance tests on the ageing behaviour of engine components when using new fuels of all kinds

- Automated endurance tests on the ageing behaviour of exhaust aftertreatment systems when using all types of new fuels

- Analyses of lubricating oil ageing when using new fuels of all types and origins.

- Assessment of thermal and mechanical component stresses on combustion chamber-enclosing components under reproducible, controlled conditions

The automation platform is used for the following projects:

- LowC "Safe and sustainable low-carbon fuels for heavy-duty, aviation, and maritime sectors"

- NH3-STAT of the BMWK

- H2-MAM hydrogen combustion engine for mobile machinery, sub-project: Combustion process development of the BMWI

- CAMPFIRE CF08_2.3 Numerical and experimental analysis of an NH3 cracker engine propulsion system for inland vessels with internal combined heat and power generation

- Investigation of the cold start behaviour of exhaust gas aftertreatment systems for methane-fuelled gas engines

This project is/was co-funded by the European Union from the European Regional Development Fund 2021-2027.

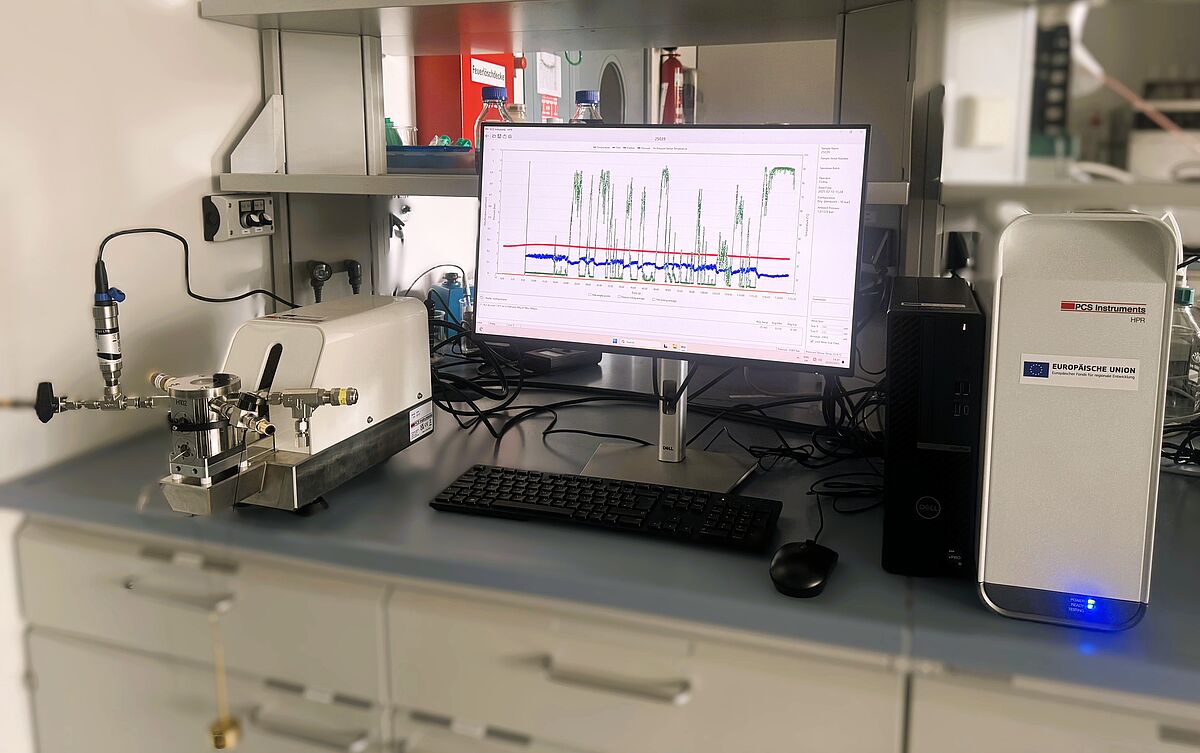

High Pressure rig - HPR

Hydrogen-based fuels such as methanol or gaseous fuels like hydrogen and ammonia for combustion engines are the subject of current research, especially in the field of maritime shipping. However, when used in engines with fuel-lubricated injection components, these fuels present the challenge of having very poor lubricity. With the High Pressure Rig – HPR, the lubricity of volatile and gaseous fuels can be tested, and component wear on various material pairings can be examined in the laboratory. Based on these results, excessive wear can be prevented in advance, and new wear-resistant component materials, coatings, and additive concepts can be developed. The new measurement system is a fully automated next-generation friction and wear testing device, equipped with a fully sealed pressure chamber that can operate under high pressure. Its unique, removable chamber design maintains pressure even outside the system, allowing test mixtures to be prepared directly on-site. The measurement system offers a fast and reliable method for testing volatile and gaseous fuels. Thanks to commercially available and interchangeable test specimens and the small required sample volumes, the system is also highly cost-efficient. In the field of lubricant research, the behavior of sustainable lubricating oils with functional water content can also be investigated, for example in gearbox lubrication – especially in the context of superlubricity, aiming to achieve extremely low friction coefficients.

Heart Cutting 2-D GC-System mit MSD, FID, NPD und FPD

With support from the European Regional Development Fund (ERDF), a Heart Cutting 2-D GC system with MSD, FID, NPD and FPD was put into operation at the department of Piston Machines and Internal Combustion Engines on 10 January 2022.

Many current projects and issues in the fields of power and lubricant research at the LKV are based on the identification and quantification of trace components in fossil and synthetic power and lubricant matrices. Two-dimensional gas chromatography is a powerful separation method for organic mixtures. In complex fuel matrices with 500 to 1000 components, polar trace components often overlap, making their identification difficult or impossible without extensive sample preparation. Polar trace components in fuels are important for the swelling behaviour of sealing materials, the tendency to form deposits and the lubricity in injection systems, among other things. With the new measuring system, these polar trace components can be separated on a second column based on polarity differences, assigned to specific substance groups and identified. The possibility of injecting larger sample volumes of up to 5 µl with the temperature-programmable evaporator also supports this separation task.

The 8890 GC system, coupled with a Deans switch to either FID and FPD Plus or MSD with backflush, delivers proven reproducible analyses of heavy hydrocarbon distillates with a carbon chain distribution from C10 to C70. This also allows detailed statements to be made about the composition of future marine fuels (ULSFO).

The acquisition of the 2D GC-MS system with various element-selective/specific detectors has expanded and strengthened the LKV's expertise in the following areas:

- Development, evaluation and testing of sustainable marine fuels from waste materials and their blends

- Optimisation of drop-in fuels for the marine sector, fuel blending

- Provision of substance data for combustion process development and for tests in the high-pressure injection chamber

- Identification of ageing and nitration products in lubricating oils

- Analysis of special fuels

- Identification of fuel ageing products

- Development of new analysis methods for oil monitoring

Simulation platform for engine test beds

With support from the European Regional Development Fund (ERDF), a simulation platform for engine test benches was put into operation at the Chair of Piston Machines and Internal Combustion Engines on 15 September 2021.

The simulation platform for engine test benches is an extension of modern test bench control systems. With this extension, the parallel operation of engines in drive trains can be simulated and thus researched on the test bench. This makes it possible to investigate the interaction of electric motors and combustion engines in an application such as forklift trucks or river boats. The device can then be used to simulate all hybrid applications and thus prepare them for the engine test bench. The device thus serves a strategic purpose in the energy transition in transport.

The simulation platform has the following technical characteristics

- Determinism in dynamically coupled real-time control loop with the test bench

- The platform has a development environment with which real-time applications can be generated and executed.

- The platform contains all the functional components required to generate corresponding real-time applications (e.g. compilers).

- The platform is compatible with the automation systems available in the test field at the University of Rostock (AVL Puma Open 1.4.x, 1.5.x).

- The platform offers a high degree of flexibility with regard to distributed modelling and simulation, thus supporting a ‘multi-tool’ and ‘multi-rate’ simulation approach within the framework of real-time co-simulation.

The simulation platform is used for the following projects:

- Ammonia Engine – Ammonia as the maritime fuel of the future

- Technology Evaluation for Marine Engines for GHG Targets 2030+ (TEME2030+) Novel technology concepts for the effective reduction of greenhouse gas emissions from gas-based large marine engines

- Multiple injection strategies for optimising mixture formation and combustion in large diesel engines to achieve the lowest CO2 and pollutant emissions when using marine fuels

- Investigation of the cold start behaviour of exhaust aftertreatment systems for methane-powered gas engines

This project is/was co-financed by the European Union from the European Regional Development Fund. Operational Programme Mecklenburg-Western Pomerania 2014-2020 ‘Investments in Growth and Employment’

3D-Laser Scanning Microscope

With support from the European Regional Development Fund (ERDF), a new laser scanning microscope was put into operation at the Chair of Piston Machines and Internal Combustion Engines on 28 August 2015.

The 3D laser scanning microscope is a light microscope in which a focused laser beam scans a specimen. This enables it to perform contactless profile, roughness and layer thickness measurements in the micrometer range on almost any material.

The strengths of the measuring system are:

- Precise measurements thanks to laser scanning

- 3D measurements in colour

- Roughness measurements in the nanometre range

- Depth-of-field colour images

This device system has a violet laser (λ = 408 nm, laser class II) and enables measurements with a height resolution in the z-direction of up to 0.5 nm.

Keyence VK-X200

- Optical system: Confocal pinhole

- Total magnification: up to 28,800x (full image on 23-inch monitor)

- Detectable image field: 11 - 5400 µm

- Laser measurement speed: 4- 7900 Hz

Titration System

Many current projects and research questions in the field of renewable fuels and their interaction with engine lubricating oil, such as component corrosion in the oil circuit, testing new lubricating oil components, effectiveness tests of new bio-based additives, and investigating causes/assessing damage to components in test bench runs at our department, rely on precise water determination in lubricating oils using Karl Fischer titration. Water in lubricants impairs lubricant film formation and is a cause of corrosion in machines and systems. In order to investigate such phenomena, it is necessary to be able to determine the water content in the lubricating oil accurately. Since engine oils almost always contain additives that undergo side reactions with the Karl Fischer reagents and simulate an excessively high water content, the indirect water determination method according to Karl Fischer must be used. In this method, the water is first removed from the sample by heating, transferred to the measuring cell with a gas stream and then determined coulometrically. This method is also useful for determining the water content in residual oils for maritime shipping, as these also contain interfering substances such as hydrogen sulphide and mercaptan sulphur.

The acquisition of the titration system for indirect water determination according to Karl Fischer has expanded and strengthened the LKV's expertise in the following areas:

- Evaluation of engine oils in test bench operation/field trials or practical tests (oil monitoring)

- Engine/combustion process development, lubricant research

- Mechanisms of oil ageing due to new petrol fuels (alcohol blends)

- Component corrosion due to water ingress into lubricating oil

- Development of new sustainable fuels for maritime shipping (water determination in residual fuels and their blends)

The titration system was funded by the state of Mecklenburg-Western Pomerania with funds from the European Regional Development Fund (ERDF), funding period 2018-2019.

Electric steam generator

With support from the European Regional Development Fund (ERDF), a new electric steam generator was put into operation at the Chair of Piston Machines and Internal Combustion Engines on 29 March 2018.

The electric steam generator is used to preheat alternative fuels for tests in large engines. The LKV Chair uses the electric steam generator to conduct comprehensive research in the field of large engines, particularly for shipping, which involves the use of highly viscous fuels.

The steam generator has the following technical characteristics:

Heating: electric

Steam output: 97 kg/h

Heat output: 72 kW

Operating pressure: 6 bar

This device system is used for the following projects:

- Modelling of emissions and fuel consumption during ship manoeuvring, MEmBran

- ηup – etaup - Increasing the overall efficiency and reducing friction losses in medium-speed marine engines

- Multiple injection strategies for optimising mixture formation and combustion in large diesel engines to achieve the lowest possible CO2 and pollutant emissions when using marine fuels

- Measurement of particles and soot as part of the UBA project ‘Analysis and further development of climate protection measures in maritime transport, taking into account current developments at international and European level’