SAARUS

Optimisation of scrubber exhaust gas cleaning technology to reduce environmentally harmful ship emissions

Project objective

The objective of the project is to reduce ship-based emissions through optimised and expanded exhaust gas cleaning to protect the atmospheric and maritime environment. The focus is on emissions of fine particles measuring less than 2.5 μm (PM2.5).

Furthermore, the pollution caused by incomplete fuel combustion will be investigated. With the entry into force of the new IMO regulations (sulphur content in fuel < 0.5% or use of an exhaust gas cleaning system), a change in the composition of emissions is to be expected. When using an exhaust gas cleaning system (gas scrubbing), the very small particles that are difficult to reduce are particularly problematic. In addition to aerosols, the wash water is also subject to only minimal regulation, meaning that pollutant-laden particles can enter the marine environment.By using an exhaust gas scrubber with a downstream particle filter and wash water treatment, as well as highly sensitive process and emission measurement technology and simulations, we aim to optimise the individual process steps within the three-year project period, resulting in an overall reduction in emissions as follows:

- Highly efficient separation of 90% of both the total particle mass and the particle fraction 2.5–0.1 μm

- 90% reduction in the number of micro-particles (1.0–0.1 μm)

- Compliance with environmental quality standards in the field of water policy (2008/105/EC)

- Turbidity value of the wash water < 25 NTU

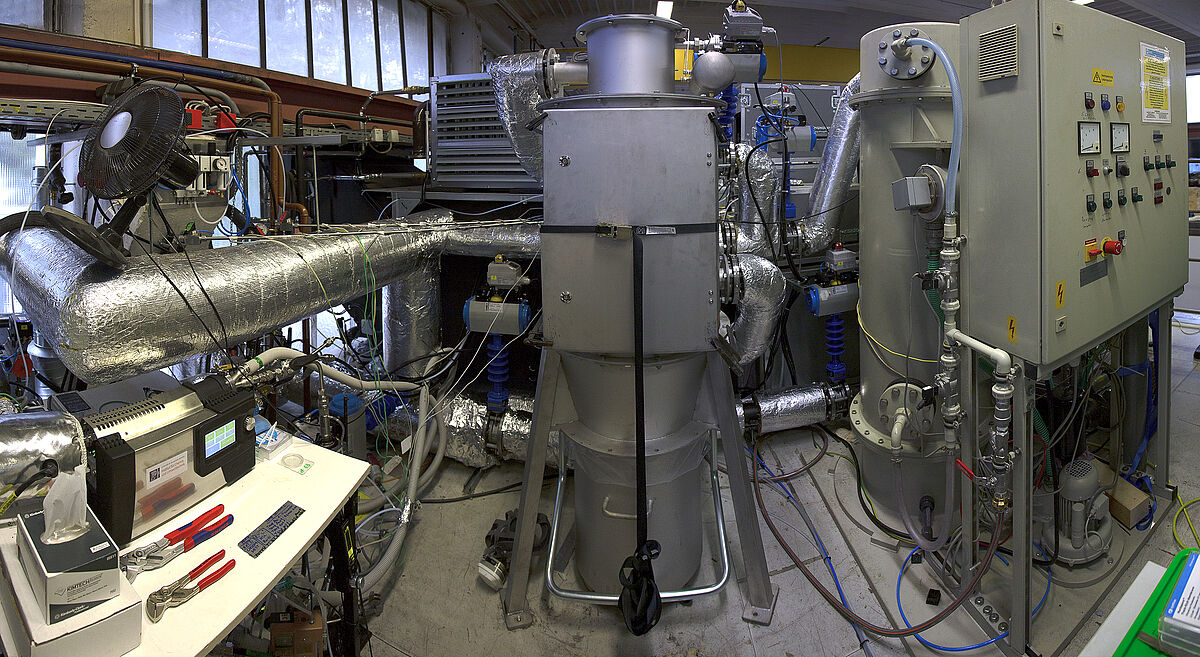

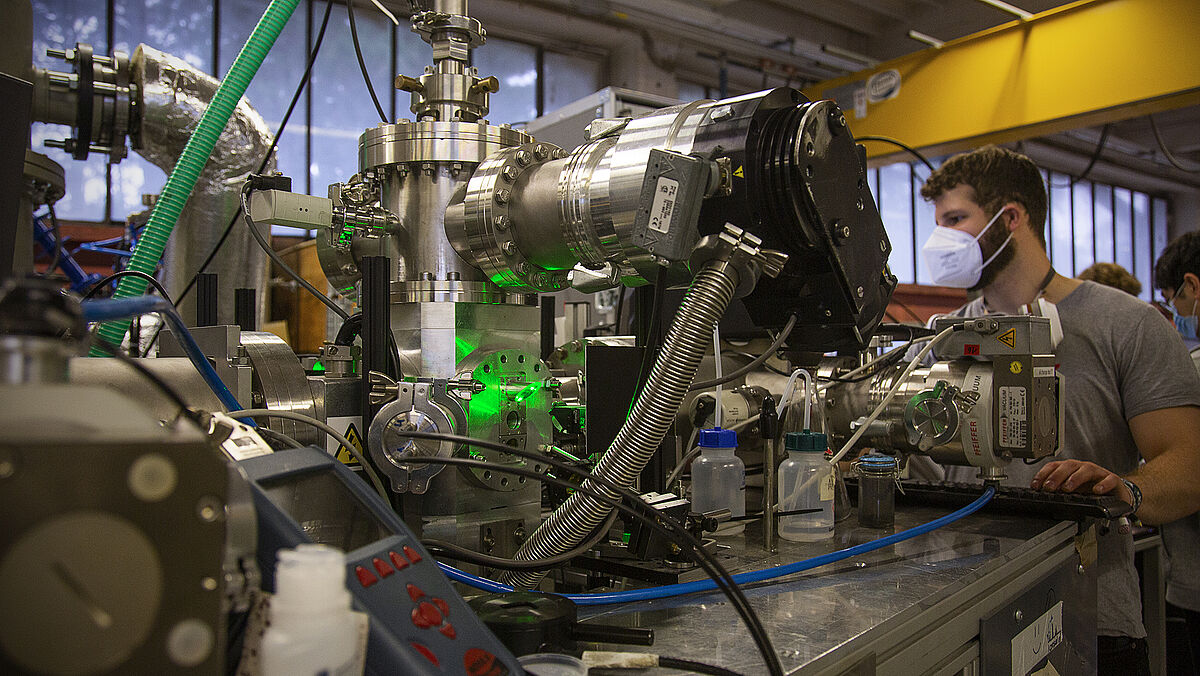

In the sub-project at the University of Rostock, marine engine technology is being adapted for operation with scrubbers and various fuels with varying sulphur contents are being used. The engine is being run in three measurement campaigns to evaluate the use of the scrubber. For this purpose, extensive physical and chemical characterisation of the emitted particles is planned, including

size distribution, chemical analysis on filters and online as individual particles.

Project website: www.saarus.de

Contribution of the University of Rostock

- Provision of the engine test bench

- Organisation and implementation of measurement campaigns

- Evaluation of measurement data, derivation of optimisation measures

- Modelling and simulation of SOx and particle separation in the scrubber

Funding body: BMWi / PTJ

Project duration: October 2019 - November 2022

Funding volume: €1.5 million (LKV) / €3.5 million (total)

Project team:

Project partners:

- Leibniz Institute for Baltic Sea Research Warnemünde IOW

- University of Rostock, Analytical Chemistry

- University of the Federal Armed Forces Munich, Institute for Chemistry and Environmental Technology

- SAACKE GmbH, Bremen

- AVL Deutschland GmbH, Munich

- GEA Westfalia Separator Group GmbH, Oelde

- SULT GmbH, Nufringen

- RVT Process Equipment GmbH, Steinwiesen

- SICK Engineering GmbH, Ottendorf-Okrilla (associated partner)